Applications of Embossing on Breathable Membranes

Applications of Embossing on Breathable Membranes

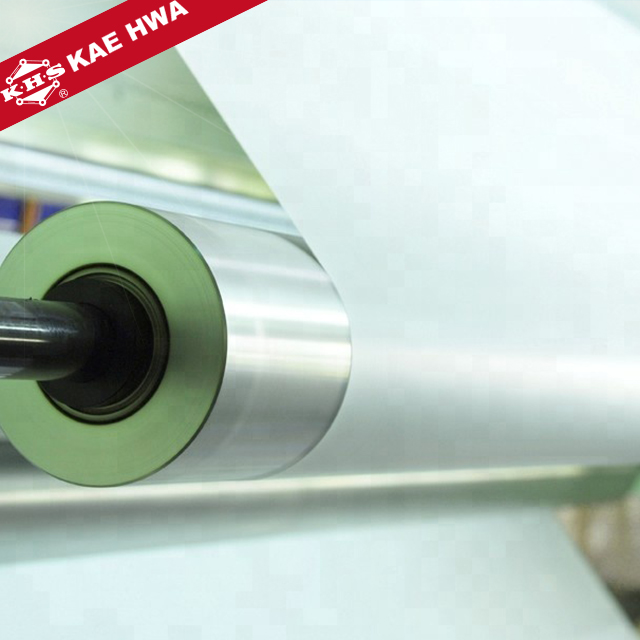

Our embossed breathable PE film combines excellent breathability, waterproof performance, and an attractive appearance. Through our embossing technique, the film gains a textured surface that enhances both functionality and aesthetics.

1. Enhanced Moisture Management and Aesthetics in Outdoor Apparel

Outdoor apparel demands high-performance fabrics that can withstand diverse environmental conditions while maintaining user comfort. Breathable membranes with embossed patterns offer a unique advantage in outdoor wear by improving moisture-wicking capabilities and air circulation. This embossing process creates fine textures on the membrane surface, which can channel moisture more effectively and prevent condensation. Additionally, embossing allows brands to integrate unique designs directly into the fabric, creating a visual identity without compromising the functionality of the membrane. By selecting embossing patterns that align with the brand’s identity, manufacturers can offer differentiated products that enhance both comfort and aesthetic appeal.

2. Improved Barrier Protection in Medical and Hygiene Products

Embossed breathable membranes are commonly used in medical textiles such as protective garments, isolation gowns, and even wound dressings. Embossing provides enhanced structural integrity and strength, especially for high-barrier applications where protection from fluids, viruses, and bacteria is critical. Embossing techniques create ridges and textures that increase the membrane's resilience without increasing thickness or weight, ensuring comfort for the user. Moreover, embossing can help improve the breathability of the membranes by creating micro-channels, which facilitate better air and moisture exchange, a crucial factor for comfort in prolonged usage. In hygiene products, embossed breathable membranes serve as soft, skin-friendly layers with improved moisture permeability and controlled airflow, contributing to dryness and comfort.

3. Durability and Ventilation in Packaging Solutions

For packaging applications, breathable membranes are often embossed to enhance their durability and adaptability to various product forms. Embossing strengthens the membrane's surface, making it more resistant to wear and tear. This is particularly beneficial in packaging for items that require a longer shelf life or controlled atmospheric conditions, such as food, desiccants, and agricultural products. The embossing process enables the membrane to withstand stress and puncture, which is essential in maintaining product integrity. Furthermore, embossed breathable membranes offer improved ventilation by allowing controlled air exchange, reducing the risk of moisture buildup inside packaging. This property is particularly advantageous in applications like desiccant bags or packaging for moisture-sensitive products, where regulated airflow is essential for product preservation.

4. Structural Benefits in Agricultural Applications

In agriculture, embossed breathable membranes are increasingly used as crop covers and mulch. The embossed patterns help regulate heat and moisture while providing shading and protection from pests. The texture from embossing also enhances the stability of the membrane when applied to soil, preventing slippage and ensuring better crop protection. Customizable embossing patterns enable manufacturers to design membranes tailored to specific crop requirements, balancing moisture retention with ventilation to support crop growth. Embossed membranes are particularly beneficial in greenhouses, where controlled environmental factors like humidity and temperature are crucial for optimal plant development.

The applications of embossing on breathable membranes extend beyond mere aesthetics. In outdoor apparel, medical and hygiene products, packaging, agriculture, and more, embossing enhances the functional attributes of these materials, from moisture management and durability to structural stability and customization. With embossing, manufacturers can deliver improved comfort, protection, and visual appeal, meeting the rigorous demands of modern consumers and industries alike. As industries continue to evolve, the versatility and enhanced functionality provided by embossing on breathable membranes will remain pivotal in meeting the growing need for innovative, high-performance materials.