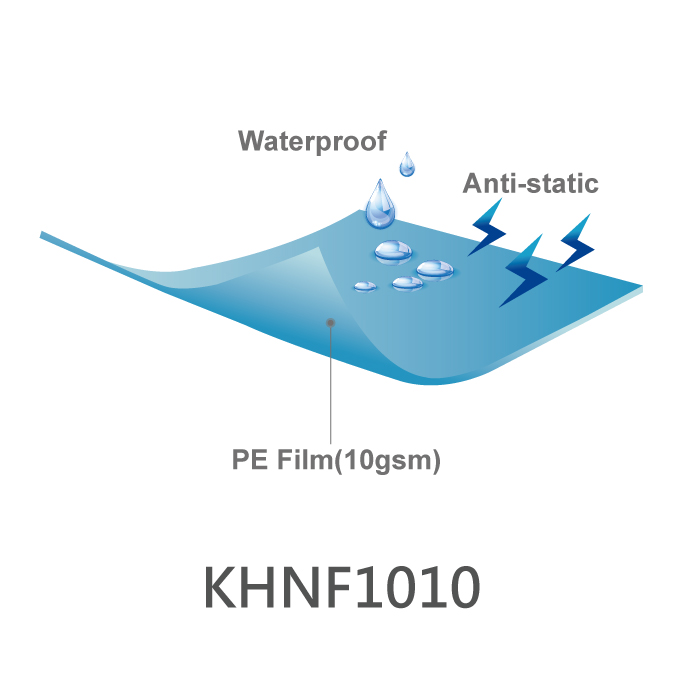

Printing PE Film

Printing PE Membrane

Printing PE membrane is commonly used as packaging material after printing. It offers several advantages such as anti-virus, anti-mite, water repellent, anti-blood, anti-static, biohazard. Additionally, it can accurately reproduce the shape and color of the packaged items. Polyethylene membrane, a colorless, tasteless, odorless, translucent, and non-toxic insulating material, is widely used for packaging bags, food bags, and various containers. However, due to its inert nature, printing on polyethylene membrane requires special processing for optimal results.

The printing methods for polyethylene membrane include flexographic, gravure, and screen printing. To ensure successful printing, the ink used should have high viscosity and strong adhesion, enabling the ink molecules to firmly adhere to the dry plastic surface. It should also dry easily with the help of oxygen in the air. Gravure printing on plastic membranes typically involves thoroughly grinding and dispersing synthetic resins, organic solvents, and pigments based on alcohols. This creates a colloidal fluid with excellent flowability. The ink used is volatile and dries quickly, offering efficient printing, strong durability, vibrant colors, and rapid drying. This type of ink is suitable for gravure rotary machines used for printing on polyethylene membrane.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Key Feature:

- Superior waterproof performance: It effectively blocks external moisture, providing reliable protection.

- Moisture and Oxidation Resistance: Offers excellent protection against moisture and oxidation, extending product shelf life.

- High Color and Shape Reproduction: High-quality printing techniques ensure accurate reproduction of product design.

- Eco-Friendly Material: Colorless, odorless, and non-toxic, making it suitable for food packaging.

- Special Treatment for Printing: Utilizes flexographic, gravure, and screen printing technologies to ensure clear, durable, and long-lasting prints.

- Fast Drying: Uses high-viscosity, quick-drying volatile inks, enhancing production efficiency with fast and convenient printing.

| Name | Specification |

| Material | Polyethylene |

| Weight | 10 - 100 gsm |

| Width | 80mm - 2000mm |

| Length | 2000M |

| Surface Treatment | Up to 4 colors printed will allow to imitate multiple colorful print |

| Application | Packing, Industrial, Medical, Hygiene, Agricultural |

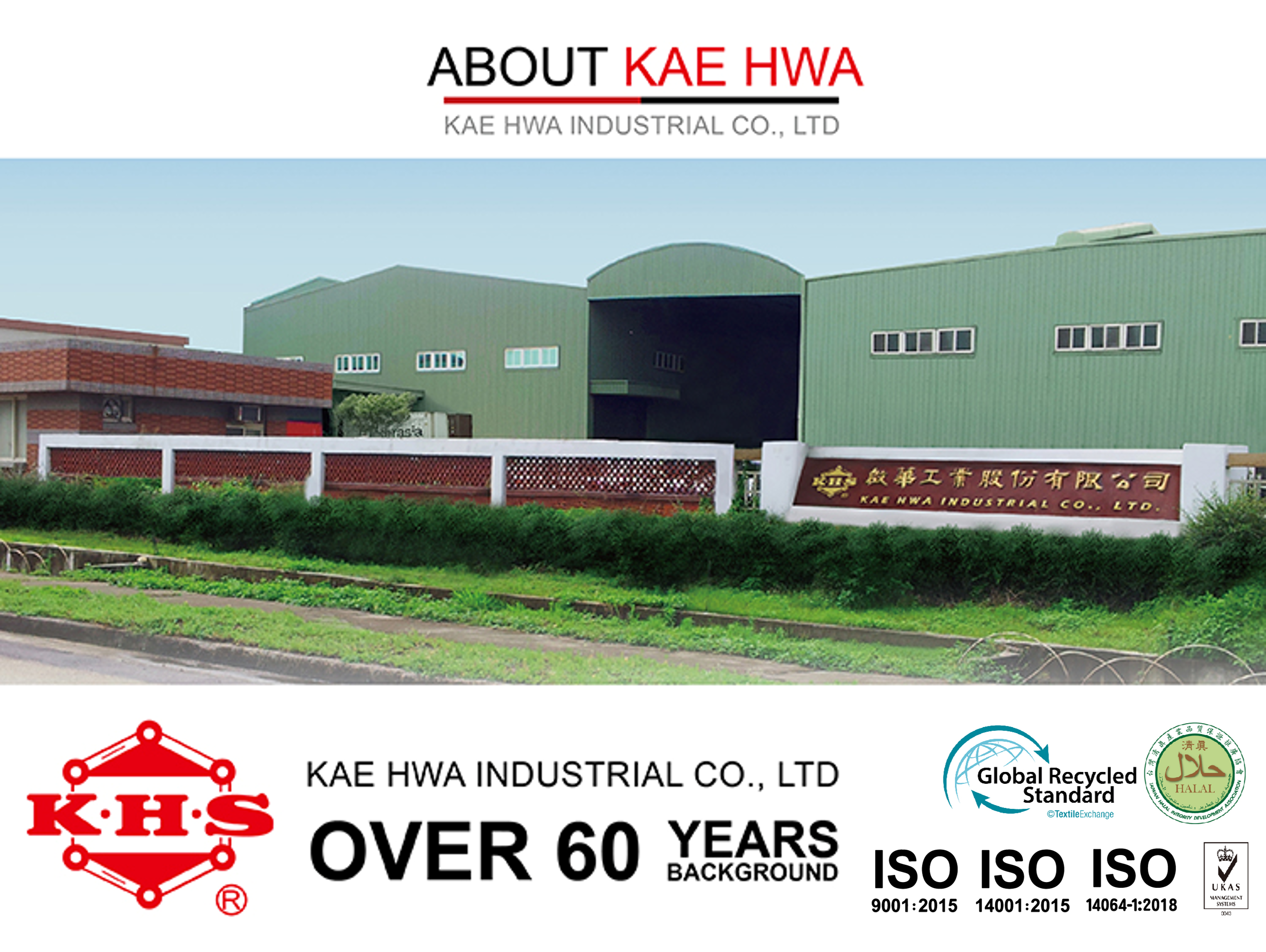

Company Profile

Kae Hwa Industrial is a professional factory, founded in 1964, specializing in the production of breathable waterproof membrane and textile in Taiwan. Our main application of the product is medical fabric (AAMI L4), Industrial protective fabric (Type 4B 5B 6B), Hygiene fabric of diaper, napkin, underpad backsheet, construction fabric of house wrapping, agricultural fabric for mulch, consumer fabric of desiccant, dehumidifier, deodorant, warm pack packaging and GRS-certified outdoor functional fabric for outdoor jackets.

We are certified many certification of ISO 9001:2015, 14001:2015, 14064-1:2018, Halal and GRS to improve our products.

Your Choice, Our Responsibility